Coated PP woven bag, BOPP Laminated Bags Manufacturing Process

Coated PP woven bag, BOPP Laminated Bags Manufacturing Process

所属分类:

Products Series and Flow Chart

产品附件:

联系我们

产品描述

多行文本内容元素

富文本内容绑定数据后可解析HTML语言内容

Coated PP woven bag, BOPP Laminated Bags Production Line

Mixer and Drying Machine

The mixer can mix the material completely. The capacity is 100 kg /h to full the tank. The power motor is the gear reduction motor 11 kw. The dimension is 630 mm x 520 mm x 1150 mm.

High Speed Flat Yarn Making Machine (YX-PLG1200)

This equipment is suitable for producing PP/HDPE tape for woven bag, cement bag, sunshade net, tarpaulin, jumbo bag, geotextile, etc. It’s maximum pp melting output up to 320 kg/hour. The main electrical components adopt international brand products with international federal insurance. The main technical indicators of this machine have reached the international advanced level, with fast speed, high output, low energy consumption, good tape quality.

The Mini Six Shuttle Circular Loom (YX-850/6)

This is new standard of circular loom, which is wearing less, less electrical power consumption and high productivity. The circular loom is doing tubular weaving, the max. speed up to 180 rpm/minute, its capacity can reach to 140 meters/hour auto stop system of warp & weft yarn braken/finished and auto compensation system of weaving will make machine has no empty weaving.

The Mini Four Shuttles Circular Loom (YX-750/4)

The circular loom is doing tubular weaving; the max. speed up to 190 rpm/minute, its capacity can reach upto 92 m/hour auto stop system of warp & weft yarn braken/finished.

Rotogravure Printing Machine (YX-RF800)

This printing machine is specifically designed to meet the needs of multi-color continuous printing and can process various roll film materials such as BOPP, PET, and PVC. With subsequent laminating processes, the printed patterns can remain vibrant and durable, making it widely used in high-end printing products. The max. printing speed 160m/minute and can handle both large-scale production and fine printing with ease.

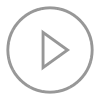

High Speed Plastic Extrusion Coating Machine(YX-90-M900)

Double extruder and Double die, and complete the double sided lamination in one time process. Equipped with the latest auto registration for higher accurate color match on both side. Higher speed and easier operation, less worker. Suitable for laminating the PP&LDPE woven fabrics, Non-woven fabrics, Kraft-paper etc.Laminating Width: 250-850mm

The High Speed Auto Cutting & Sewing Machine (YX-QF800)

Fully automatic conversion line with servo motor designed to produce bottom fold-sewn bags from tubular cloth roll which is not only dramatically reduces labor consumption, but also in high productivity while maintain stable quality. The line, including cutting, sewing, count stacking sections, with its unique design, employed marginal moving parts, which not only very easy to operate but also minimal maintenance required.

Details

Coated PP woven bag, BOPP Laminated Bags Production Line

Mixer and Drying Machine

The mixer can mix the material completely. The capacity is 100 kg /h to full the tank. The power motor is the gear reduction motor 11 kw. The dimension is 630 mm x 520 mm x 1150 mm.

High Speed Flat Yarn Making Machine (YX-PLG1200)

This equipment is suitable for producing PP/HDPE tape for woven bag, cement bag, sunshade net, tarpaulin, jumbo bag, geotextile, etc. It’s maximum pp melting output up to 320 kg/hour. The main electrical components adopt international brand products with international federal insurance. The main technical indicators of this machine have reached the international advanced level, with fast speed, high output, low energy consumption, good tape quality.

The Mini Six Shuttle Circular Loom (YX-850/6)

This is new standard of circular loom, which is wearing less, less electrical power consumption and high productivity. The circular loom is doing tubular weaving, the max. speed up to 180 rpm/minute, its capacity can reach to 140 meters/hour auto stop system of warp & weft yarn braken/finished and auto compensation system of weaving will make machine has no empty weaving.

The Mini Four Shuttles Circular Loom (YX-750/4)

The circular loom is doing tubular weaving; the max. speed up to 190 rpm/minute, its capacity can reach upto 92 m/hour auto stop system of warp & weft yarn braken/finished.

Rotogravure Printing Machine (YX-RF800)

This printing machine is specifically designed to meet the needs of multi-color continuous printing and can process various roll film materials such as BOPP, PET, and PVC. With subsequent laminating processes, the printed patterns can remain vibrant and durable, making it widely used in high-end printing products. The max. printing speed 160m/minute and can handle both large-scale production and fine printing with ease.

High Speed Plastic Extrusion Coating Machine(YX-90-M900)

Double extruder and Double die, and complete the double sided lamination in one time process. Equipped with the latest auto registration for higher accurate color match on both side. Higher speed and easier operation, less worker. Suitable for laminating the PP&LDPE woven fabrics, Non-woven fabrics, Kraft-paper etc.Laminating Width: 250-850mm

The High Speed Auto Cutting & Sewing Machine (YX-QF800)

Fully automatic conversion line with servo motor designed to produce bottom fold-sewn bags from tubular cloth roll which is not only dramatically reduces labor consumption, but also in high productivity while maintain stable quality. The line, including cutting, sewing, count stacking sections, with its unique design, employed marginal moving parts, which not only very easy to operate but also minimal maintenance required.