Mesh Bag Manufacturing Process

产品描述

多行文本内容元素

富文本内容绑定数据后可解析HTML语言内容

Mesh Bag Production Line

Mixer and Drying Machine

The mixer can mix the material completely. The capacity is 100 kg /h to full the tank. The power motor is the gear reduction motor 11 kw. The dimension is 630 mm x 520 mm x 1150 mm.

The mini extrusion machine (YX-FS115/B800)

This equipment is design for producing pp flat yarn. It’s maximum pp melting output upto 100 kg/hr, equipped with belt type screen filter changer and rotary blades slitting system, these components can save the down time for changing the iron filter and tape slitting blades, and also decrease the loss during the production. The pressure rollers of take off unit is controlled by pneumatic system, and synchronized control electronic control box to control full set machine. Our electronic tension control winder provides good wind-up flat surface quality, tape strength and even winding edge.

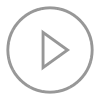

The Mesh Bag Circular Loom (YX-WYZJ-750/4)

This machine is a new generation of advanced equipment for plastic mesh tube weaving. Suit for mixed weaving of flat wire with round wire, or only flat wires, or only round wires, can be used to weave the fabrics of various specifications. The bag’s durability and flatness which made of our ciurclar loom are the same as the rapier loom/plain loom. Automatic weave, automatic thread, the all-in-one solution.

The Mesh Bag Auto Cutting & Sewing Machine (YX-H800)

The cutting sewing machine is suitable for making all kinds of onion bags,potato bags, etc. Fully automatic, intelligent combined operation , one person and one machine, and the production efficiency will increased by more than twice. Integrating multiple processing processes into one, one person can complete all processes of mesh bag . The max. production capacity can reach 36 pcs/min.

Details

Mesh Bag Production Line

Mixer and Drying Machine

The mixer can mix the material completely. The capacity is 100 kg /h to full the tank. The power motor is the gear reduction motor 11 kw. The dimension is 630 mm x 520 mm x 1150 mm.

The mini extrusion machine (YX-FS115/B800)

This equipment is design for producing pp flat yarn. It’s maximum pp melting output upto 100 kg/hr, equipped with belt type screen filter changer and rotary blades slitting system, these components can save the down time for changing the iron filter and tape slitting blades, and also decrease the loss during the production. The pressure rollers of take off unit is controlled by pneumatic system, and synchronized control electronic control box to control full set machine. Our electronic tension control winder provides good wind-up flat surface quality, tape strength and even winding edge.

The Mesh Bag Circular Loom (YX-WYZJ-750/4)

This machine is a new generation of advanced equipment for plastic mesh tube weaving. Suit for mixed weaving of flat wire with round wire, or only flat wires, or only round wires, can be used to weave the fabrics of various specifications. The bag’s durability and flatness which made of our ciurclar loom are the same as the rapier loom/plain loom. Automatic weave, automatic thread, the all-in-one solution.

The Mesh Bag Auto Cutting & Sewing Machine (YX-H800)

The cutting sewing machine is suitable for making all kinds of onion bags,potato bags, etc. Fully automatic, intelligent combined operation , one person and one machine, and the production efficiency will increased by more than twice. Integrating multiple processing processes into one, one person can complete all processes of mesh bag . The max. production capacity can reach 36 pcs/min.