Jumbo Bag Production Line

产品描述

多行文本内容元素

富文本内容绑定数据后可解析HTML语言内容

Jumbo Bag Production Line

Mixer and Drying Machine

The mixer can mix the material completely. The capacity is 100 kg /h to full the tank. The power motor is the gear reduction motor 11 kw. The dimension is 630 mm x 520 mm x 1150 mm.

High Speed Flat Yarn Making Machine (YX-PLG1200)

This equipment is suitable for producing PP/HDPE tape for woven bag, cement bag, sunshade net, tarpaulin, jumbo bag, geotextile, etc. It’s maximum pp melting output up to 320 kg/hour. The main electrical components adopt international brand products with international federal insurance. The main technical indicators of this machine have reached the international advanced level, with fast speed, high output, low energy consumption, good tape quality.

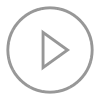

The Ten Shuttle Circular Loom (YX-FYB2600/10)

Our Ten Shuttle Circular Loom is suit for producing high density, high fiber container bag, geotextile, tarpaulin, etc. It can weave fabric width 2100mm-2550mm Dia. And the production speed can reach 1300-1400m/day. Frequency control system that precisely regulates warp feeding, fabric take-up, and cloth lifting to ensure superior fabric flatness. Bluetooth weft yarn detector, sensitive and reliable, free from dust and light line impact, safe and reliable, automatic stop after weft breaking.The unique rubber roller fabric lifting system, PLC control, with the lubrication-free flat cam mechanism, easy maintenance and low operational costs.

Super Wide Plastic Extrusion Film Compound Unit (YX120-FMS2700)

Our Super Wide Plastic Extrusion Film Compound Unit is suit for jumbo bag, geotextile, tarpaulin, super wide plastic woven fabric laminating. One process is completed on one side or two sides. The width can be customized flexibly according to the needs of users. The weight of the film is controlled by computer intelligence. PLC centralized control, HMI data display/record/setting.

Bag Cutting Machine

Our Jumbo Bag Cutting Machinew with auto jumbo-fabric roll feeding & EPC unit; man-machine display screen operation interface; Liner-knife cutting device; Cost saving, one person easy to operate; Small floor space.

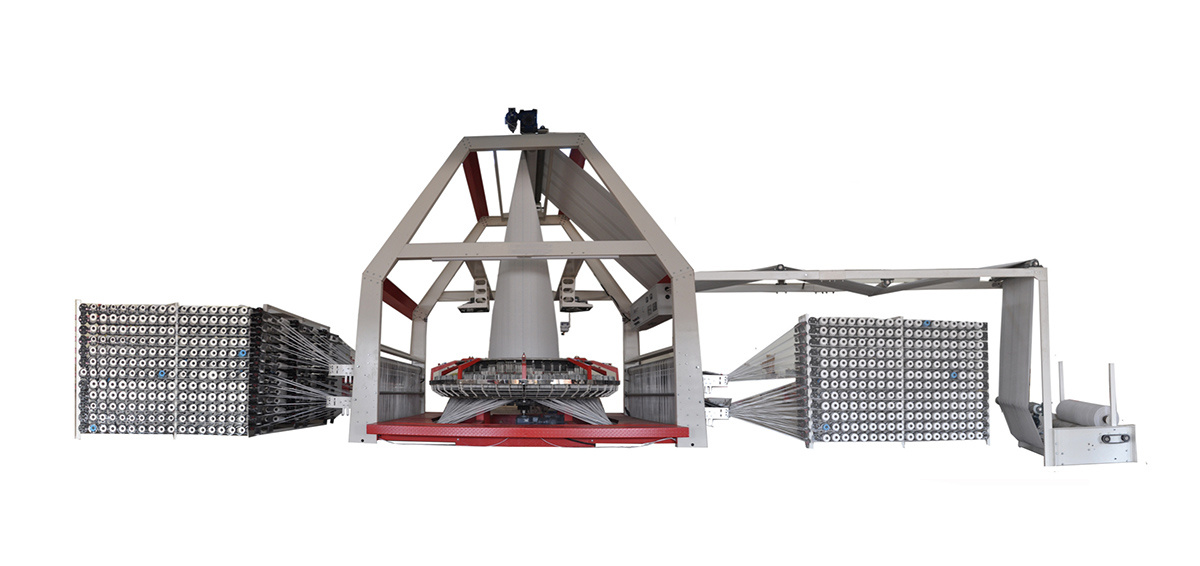

The Woven Belt Weaving Machine

Our Woven Belt Weaving Machine is a special equipment for making the sling belt and girdle belt on the container bag, it has the advantages of high speed, low energy consumption, smooth running, low noise, high degree of automation, sensitive and reliable operation, and so on.

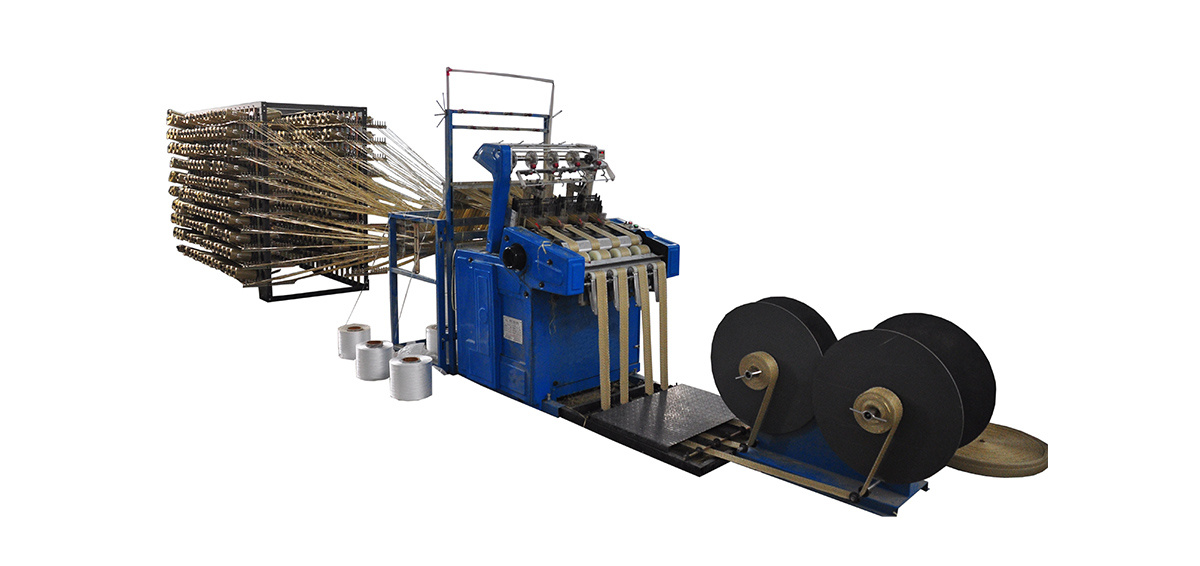

Belt Cutting Machine

Our Belt Cutting Machine is suit for producing the container sling belt, girdle belt, binding belt, safety belt, luggage belt, etc. The machine use electrical appliances as power source, electric heating knife.Set automatic fixed length, automatic dotting and automatic cutting in one.High precision servo motor is used to feed belt to cut,internal control system using PLC programmable control, operation interface for high-tech products man-machine interface.The machine is not only beautiful in appearance, easy to operate and maintain, but also fast in speed, low energy consumption and high automation.

Jumbo Bag Printing Machine

Our Jumbo Bag Printing Machine is specially designed for jumbo bag printing. 1 to 5 color printing provided according to customer's demand. Suitable printing material size up to 1800 mm (W) x 2200 mm (L). Suitable printing area up to 1200 mm (W) x 1800 mm (L).

Sewing Machine

Our Sewing Machine adopts full rotary axe and shuttle, suitable for sewing of container bags, tents, chair cushions, polishing wheels (cloth wheels), car canopies, tarpaulins, suitcases and bags, jeans etc. Precise feeding when sewing, the upper and lower materials will not slip, so after sewing it is beautiful. Large rotary shuttle, up and down feeding to make sewing thick material more easily.

Details

Jumbo Bag Production Line

Mixer and Drying Machine

The mixer can mix the material completely. The capacity is 100 kg /h to full the tank. The power motor is the gear reduction motor 11 kw. The dimension is 630 mm x 520 mm x 1150 mm.

High Speed Flat Yarn Making Machine (YX-PLG1200)

This equipment is suitable for producing PP/HDPE tape for woven bag, cement bag, sunshade net, tarpaulin, jumbo bag, geotextile, etc. It’s maximum pp melting output up to 320 kg/hour. The main electrical components adopt international brand products with international federal insurance. The main technical indicators of this machine have reached the international advanced level, with fast speed, high output, low energy consumption, good tape quality.

The Ten Shuttle Circular Loom (YX-FYB2600/10)

Our Ten Shuttle Circular Loom is suit for producing high density, high fiber container bag, geotextile, tarpaulin, etc. It can weave fabric width 2100mm-2550mm Dia. And the production speed can reach 1300-1400m/day. Frequency control system that precisely regulates warp feeding, fabric take-up, and cloth lifting to ensure superior fabric flatness. Bluetooth weft yarn detector, sensitive and reliable, free from dust and light line impact, safe and reliable, automatic stop after weft breaking.The unique rubber roller fabric lifting system, PLC control, with the lubrication-free flat cam mechanism, easy maintenance and low operational costs.

Super Wide Plastic Extrusion Film Compound Unit (YX120-FMS2700)

Our Super Wide Plastic Extrusion Film Compound Unit is suit for jumbo bag, geotextile, tarpaulin, super wide plastic woven fabric laminating. One process is completed on one side or two sides. The width can be customized flexibly according to the needs of users. The weight of the film is controlled by computer intelligence. PLC centralized control, HMI data display/record/setting.

Bag Cutting Machine

Our Jumbo Bag Cutting Machinew with auto jumbo-fabric roll feeding & EPC unit; man-machine display screen operation interface; Liner-knife cutting device; Cost saving, one person easy to operate; Small floor space.

The Woven Belt Weaving Machine

Our Woven Belt Weaving Machine is a special equipment for making the sling belt and girdle belt on the container bag, it has the advantages of high speed, low energy consumption, smooth running, low noise, high degree of automation, sensitive and reliable operation, and so on.

Belt Cutting Machine

Our Belt Cutting Machine is suit for producing the container sling belt, girdle belt, binding belt, safety belt, luggage belt, etc. The machine use electrical appliances as power source, electric heating knife.Set automatic fixed length, automatic dotting and automatic cutting in one.High precision servo motor is used to feed belt to cut,internal control system using PLC programmable control, operation interface for high-tech products man-machine interface.The machine is not only beautiful in appearance, easy to operate and maintain, but also fast in speed, low energy consumption and high automation.

Jumbo Bag Printing Machine

Our Jumbo Bag Printing Machine is specially designed for jumbo bag printing. 1 to 5 color printing provided according to customer's demand. Suitable printing material size up to 1800 mm (W) x 2200 mm (L). Suitable printing area up to 1200 mm (W) x 1800 mm (L).

Sewing Machine

Our Sewing Machine adopts full rotary axe and shuttle, suitable for sewing of container bags, tents, chair cushions, polishing wheels (cloth wheels), car canopies, tarpaulins, suitcases and bags, jeans etc. Precise feeding when sewing, the upper and lower materials will not slip, so after sewing it is beautiful. Large rotary shuttle, up and down feeding to make sewing thick material more easily.