“7” Folding Mouth Cement Bag Manufacturing Process

产品描述

多行文本内容元素

富文本内容绑定数据后可解析HTML语言内容

“7” Folding Mouth Cement Bag Production Line

Mixer and Drying Machine

The mixer can mix the material completely. The capacity is 100 kg /h to full the tank. The power motor is the gear reduction motor 11 kw. The dimension is 630 mm x 520 mm x 1150 mm.

The mini extrusion machine (YX-FS115/B800)

This equipment is design for producing pp flat yarn. It’s maximum pp melting output upto 100 kg/hr, equipped with belt type screen filter changer and rotary blades slitting system, these components can save the down time for changing the iron filter and tape slitting blades, and also decrease the loss during the production. The pressure rollers of take off unit is controlled by pneumatic system, and synchronized control electronic control box to control full set machine. Our electronic tension control winder provides good wind-up flat surface quality, tape strength and even winding edge.

The Mini Six Shuttle Circular Loom (YX-850/6)

This is new standard of circular loom, which is wearing less, less electrical power consumption and high productivity. The circular loom is doing tubular weaving, the max. speed up to 180 rpm/minute, its capacity can reach to 140 meters/hour auto stop system of warp & weft yarn braken/finished and auto compensation system of weaving will make machine has no empty weaving.

The Mini Four Shuttles Circular Loom (YX-750/4)

The circular loom is doing tubular weaving; the max. speed up to 190 rpm/minute, its capacity can reach upto 92 m/hour auto stop system of warp & weft yarn braken/finished.

High Speed Plastic Extrusion Coating Machine (YX-90-M900)

Double extruder and Double die, and complete the double sided lamination in one time process. Equipped with the latest auto registration for higher accurate color match on both side. Higher speed and easier operation, less worker. Suitable for laminating the PP&LDPE woven fabrics, Non-woven fabrics, Kraft-paper etc.Laminating Width: 250-850mm

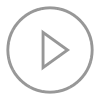

No Cylinder Change Type Flexographic Printing Line(YX-NFPG800)

Suitable to print on PP/HDPE woven fabric, non-woven fabric, kraft paper, etc by roll to roll. Servo control system, print on both sides one-time process. Equipped with double-position unwinding and back to back winder, complete automatic non-stop cloth splicing and cloth exchange. With intelligent corona treatment machine and photoelectric servo correction machine, in order to better control the accuracy of the printing position. The max. printing speed 130m/min. maintanance.

Auto Cutting and Sewing Machine with “7" Folding Mouth (YX-CSF-H700)

This unit is a professional equipment for continuous processing of the tube fabric which has already been folded with M edge, the processing steps follow as cutting tube into pieces-cutting bag mouth shape like “7”-folding bag mouth-sewing bag top-collecting bags. Machine can be operated by one person simply. It equipped with automatic deviation correction, automatic counting which can adjust the bag length and width quickly. Production speed 35-40 pcs/min.

Details

“7” Folding Mouth Cement Bag Production Line

Mixer and Drying Machine

The mixer can mix the material completely. The capacity is 100 kg /h to full the tank. The power motor is the gear reduction motor 11 kw. The dimension is 630 mm x 520 mm x 1150 mm.

The mini extrusion machine (YX-FS115/B800)

This equipment is design for producing pp flat yarn. It’s maximum pp melting output upto 100 kg/hr, equipped with belt type screen filter changer and rotary blades slitting system, these components can save the down time for changing the iron filter and tape slitting blades, and also decrease the loss during the production. The pressure rollers of take off unit is controlled by pneumatic system, and synchronized control electronic control box to control full set machine. Our electronic tension control winder provides good wind-up flat surface quality, tape strength and even winding edge.

The Mini Six Shuttle Circular Loom (YX-850/6)

This is new standard of circular loom, which is wearing less, less electrical power consumption and high productivity. The circular loom is doing tubular weaving, the max. speed up to 180 rpm/minute, its capacity can reach to 140 meters/hour auto stop system of warp & weft yarn braken/finished and auto compensation system of weaving will make machine has no empty weaving.

The Mini Four Shuttles Circular Loom (YX-750/4)

The circular loom is doing tubular weaving; the max. speed up to 190 rpm/minute, its capacity can reach upto 92 m/hour auto stop system of warp & weft yarn braken/finished.

High Speed Plastic Extrusion Coating Machine (YX-90-M900)

Double extruder and Double die, and complete the double sided lamination in one time process. Equipped with the latest auto registration for higher accurate color match on both side. Higher speed and easier operation, less worker. Suitable for laminating the PP&LDPE woven fabrics, Non-woven fabrics, Kraft-paper etc.Laminating Width: 250-850mm

No Cylinder Change Type Flexographic Printing Line(YX-NFPG800)

Suitable to print on PP/HDPE woven fabric, non-woven fabric, kraft paper, etc by roll to roll. Servo control system, print on both sides one-time process. Equipped with double-position unwinding and back to back winder, complete automatic non-stop cloth splicing and cloth exchange. With intelligent corona treatment machine and photoelectric servo correction machine, in order to better control the accuracy of the printing position. The max. printing speed 130m/min. maintanance.

Auto Cutting and Sewing Machine with “7" Folding Mouth (YX-CSF-H700)

This unit is a professional equipment for continuous processing of the tube fabric which has already been folded with M edge, the processing steps follow as cutting tube into pieces-cutting bag mouth shape like “7”-folding bag mouth-sewing bag top-collecting bags. Machine can be operated by one person simply. It equipped with automatic deviation correction, automatic counting which can adjust the bag length and width quickly. Production speed 35-40 pcs/min.