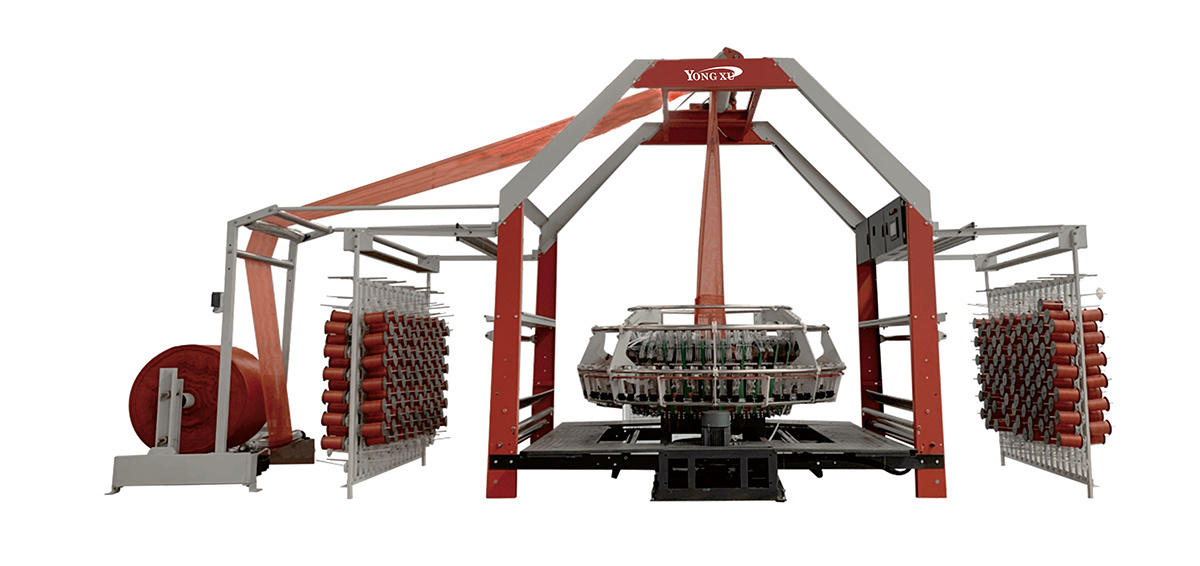

Four Shuttle Circular Loom

Greatly improve production efficiency

Keyword:Four Shuttle Circular Loom

Key words:

Classification:

Circular Loom

Four Shuttle Circular Loom

keyword: Four Shuttle Circular Loom

Whatsapp:

Details

Packaging machine: an important part of automated production

Packaging machines play a crucial role in modern industrial production lines. With the rapid development of technology, automation and intelligence have become the mainstream trends in industrial manufacturing, and packaging machines, as key equipment on production lines, are an indispensable part. Below, we will delve into the role, characteristics, and industrial applications of packaging machines.

1、 The function of packaging machine

Packaging machines are mainly used for automated operations in the product packaging process, including sealing, labeling, packaging, and other multiple stages. It can not only improve production efficiency, but also reduce labor costs, minimize errors, and enhance product quality.

2、 Characteristics of packaging machine

1. Efficiency: The packaging machine can achieve high-speed and continuous automated packaging, greatly improving production efficiency.

2. Stability: Ensure packaging quality and accuracy through precise control systems and stable mechanical structures.

3. Flexibility: Packaging methods and parameters can be adjusted according to different products to meet various packaging needs.

4. Cost savings: Reduce labor costs, minimize waste, and lower business operating costs.

3、 The application of packaging machines in the industrial field

1. Food industry: used for sealing, labeling, etc. of food packaging bags.

2. Pharmaceutical industry: used for packaging products such as drugs and medical devices.

3. Chemical industry: used for automatic filling, sealing, etc. of chemical products.

4. Daily necessities industry: used for automated packaging of daily necessities such as shampoo and shower gel.

5. Other industrial fields, such as electronic products, toys, hardware, etc., require packaging machines to complete the product packaging work.

4、 Development Trends

With the rapid development of Industry 4.0 and intelligent manufacturing, packaging machines are moving towards greater automation and intelligence. In the future, packaging machines will pay more attention to collaborative operation with other equipment on the production line, achieving comprehensive automation and intelligence of the production process.

In short, packaging machines play an indispensable role in modern industrial production lines. Its function is not only to improve production efficiency, but also to ensure product quality and reduce operating costs. With the advancement of technology, we have reason to believe that packaging machines will play a greater role in the future, creating more value for the industrial manufacturing field.

Application

To weave PP/HDPE fabric for woven bag, cement bag, rice bag, flour bag, pet food bag, animal food bag, fertilizer bag, chemical bag, etc.

Technical Data

|

S/N. |

Items |

Parameters |

||||

|

1) |

Model |

YX-FYB500/4 |

YX-FYB750/4 |

YX-FYB1200/4 |

YX-FYB1500/4 |

|

|

2) |

Shuttle |

4 Shuttles |

4 Shuttles |

4 Shuttles |

4 Shuttles |

|

|

3) |

Folded width |

120-500mm |

300-750mm |

600-1100mm |

950-1300mm |

|

|

4) |

Production speed |

2200meter/day, depend on the final width of yarn. |

2200 meter/day, depend on the final width of yarn. |

2000meter/day, depend on the final width of yarn. |

2000meter/day, depend on the final width of yarn. |

|

|

5) |

Number Of Warp Creels(pcs) |

576 |

768 |

896 |

1120 |

|

|

6) |

Main motor power(kw) |

1.5kw |

2.2kw |

2.2kw |

3kw |

|

|

7) |

Total power(kw) |

2kw |

2.7kw |

2.7kw |

3.5kw |

|

|

8) |

Prime motor rotational speed(r/min) |

160-200 |

160-200 |

150-190 |

120-160 |

|

|

9) |

Installing Dimensions(L*W*H) |

8400*2000*3200mm |

8600*2200*3200mm |

9200*2500*3200mm |

9500*2900*4000mm |

|

|

10) |

Weight(kg) |

1200 kg |

1500 kg |

1800 kg |

2000 kg |

|

Composition Of The Standard Loom

| Frame | 1 set |

| Creel Stand | 2 unit |

| Central drive system (small cam, A.C. motor) | 1 unit |

| Positive warp infeed system with torque motor | 2 unit |

| Warp break detecting system | 1 unit |

| Weft break detecting system | 1 unit |

| Weft pre exhaust detecting system | 1 unit |

| Shuttle assembly | 4 units |

| Shuttle wheel | with |

| Shuttle motion guide | 1 unit |

| Weaving size ring | 1 unit |

| Bobbin storage above the intake | 2 units |

| Manual operation control unit | 3 units |

| Fabric haul-off system | 1 unit |

| Electronic meter counter | 1 unit |

| Standard width surface winder | 1 unit |

| Loom control system | 1 unit |

Remark

* The data depends on weaving construction, size and weight of fabric, specification and quality of tape.

** Specification and dimensions are subject to change without prior notice.

*** Special specification and versions on request.

Inquiry Process

The client informs about the product specifications and weight.

We suggests machine types and offer the official offer.

After the client confirms the order details, we begins the production.

During production, we provides photos and videos, allowing the client to track and supervise the production progress in real time.

24 Hours Online Service

Installation and Debugging

The machines are loaded and shipped out.

Quality inspection is carried out.

Related Products

Online Inquiry

Tell us more so we can connect you with the right person for your request. We repects your privacy and will only use your personal data to respond to your enquiry.